Concept

Static mixer as a novel and efficient mixing device , can effectively carry out chemical process to strengthen the increasingly wide range of applications in the process industry , and even on many occasions to replace the traditional trend of stirred reactors .

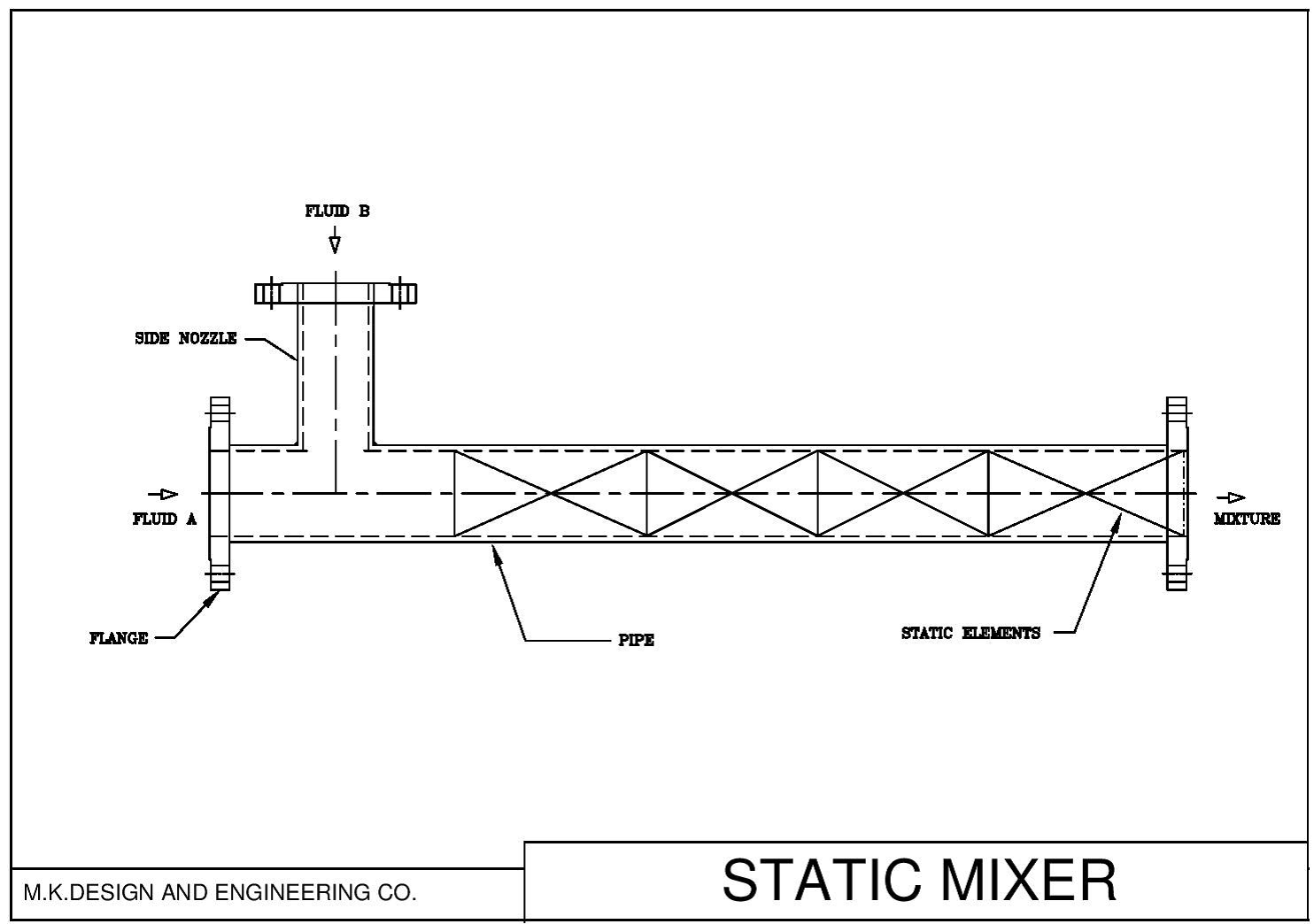

Static mixers consist of mixing elements placed on the inside of a pipe or channel. The elements are fixed and do not move. Chemicals, which are added just upstream of the elements, mix with the bulk fluid because of the complex, three-dimensional fluid motion that is generated by the elements. The shape of the elements determines the character of this fluid motion and thus determines the effectiveness of the mixer.

Working principle

When the Two or more fluids enter the Static Mixer divided in half layers. The number of layers regenerated is depending on number of elements. More number of Elements creates more number of layers. The energy needed for mixing comes from a loss in pressure as fluids flow through the static mixer.

Parts of Static Mixer

- Pipe or Housing

- Flanges

- Elements or Internals

- Side Nozzle for Secondary Liquid

Static Mixer Selection

For each application, the designer must first determine the number of mixing sections required to achieve a complete mix. The guidelines below are based upon the Reynolds Number of your system.The designer should select a diameter and/or a construction that will give the desired mixing performance without exceeding your systems maximum allowable pressure drop.

- Calculate the Reynolds Number :-

- Select a model based on the Reynolds Number:-

- Determine the Pressure Drop

Use the diameter given in the chart and calculate the Reynolds no as follows.

Re = DVp / μ

D = Inside Diameter of Pipe (mm).

V = Velocity (m/s).

ρ = Density of Fluid (kg /m3).

μ = Viscosity of fluid (cP).

For High Reynolds No

Module: SMX Equivalent

| Reynolds No | No Of Mixing elements |

|---|---|

| < 1000 | 6 |

| > 1000 | 4 |

For Low Reynolds No

Module: Kenics Equivalent

| Reynolds No | No Of Mixing elements |

|---|---|

| < 10 | 24 to 32 |

| 10 to 500 | 16 to 24 |

| 500 to 2000 | 8 to 16 |

| > 2000 | 4 to 8 |

Turbulent Flow:

Pressure Drop = ( K x V2 x ρ x (L/D)) / 2

K = Constant.

V = Velocity (m/s).

L = Length of Element.

D = Diameter of Element.

ρ = Average Density.

Laminar Flow:

Pressure Drop = (K x μ x (L/D) x (Q3/D)

K = Constant.

μ = Viscosity (Pa.s)

L = Length.

D = Diameter of Element.

Q = Flow rate (Liter/sec).

Applications:-

- Blending of miscible fluids both in Laminar and Turbulent Flow

- Mixing and Dispersion of immiscible fluids.

- Solid Blending.

- Heat and Mass transfer and homogenization.

- Gas dispersion in liquids.

Advantages

- No Moving parts hence low maintenance.

- Lower energy consumption.

- Lower investment compare to other mixers.

- Smaller space requirement.

- High Level Mixing Efficiency.

- Easy and simple installation , Start-up and operation.

- Reaction at molecular level.

Design Standard

- ASME B31.3

- ASME B16.5

- ASME B16.47

- ASME SEC VIII DIV I

- ASME SEC VI DIV A/B/C

Material of Construction

- Carbon Steel

- Carbon Steel + FRP

- Carbon Steel + PVC

- Carbon Steel + Rubber Lined

- Carbon Steel + Epoxy Coating

- Stainless Steel ( SS 304,SS 304L,SS 316,SS 316L)

- Special Alloys.

- Hastealloy

- Titanium