Concept

Mixing is one of the common unit operation employed in chemical industries. It is used for blending of liquids, homogenization of mixtures, to ensure proper heat and mass transfer in various operations, prevention of deposition of solid particles etc.

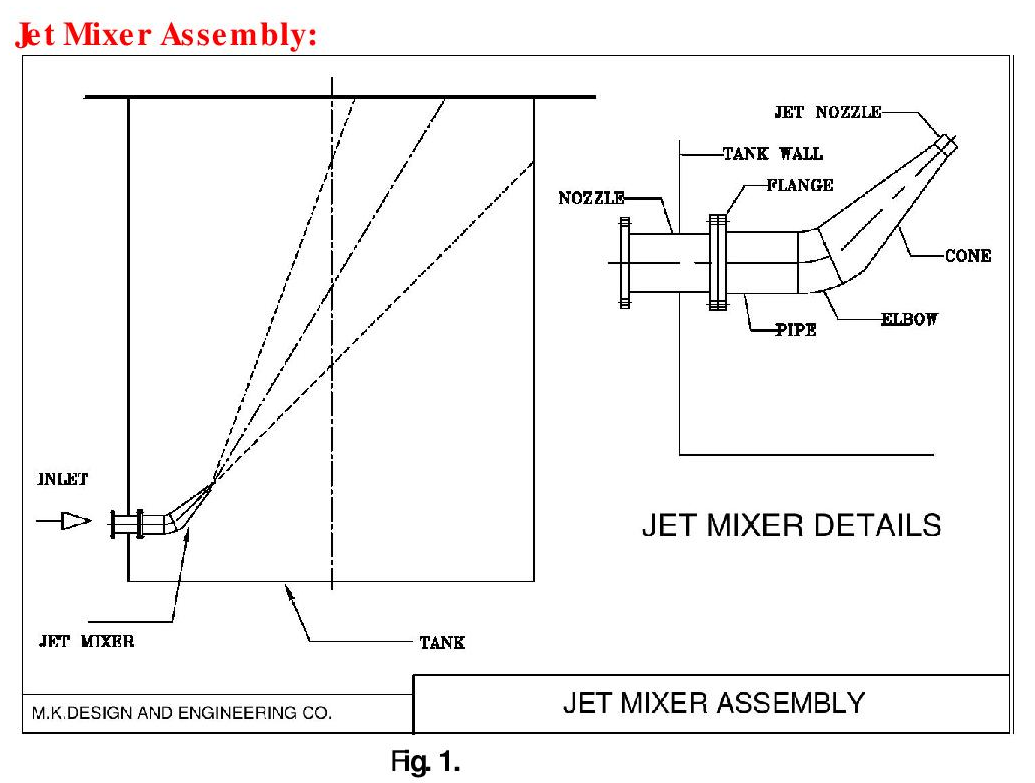

Impellers are the conventional devices used for mixing purpose in industries. But they are very expensive for large storage tanks and underground tanks. Jet mixers have become alternative to impellers for over 50 years in the process industry. In jet mixing, a part of liquid from the tank is circulated into the tank at high velocities with the help of pump through nozzles. The resulting jet of fluid entrains some of the surrounding fluid and creates a circulatory pattern, which leads to mixing in the tank.

Parts of Jet Mixer

- Flange

- Pipe

- Elbow

- Cone

- Nozzle

Working principle

Mixing in a tank is a function of momentum of the inlet flow during the fill cycles. Momentum is the product of flow and velocity. The turbulent jet of the inlet flow creates a velocity discontinuity with the liquid already in the tank. This creates turbulence and rapid mixing as the jets move away from the ports. Due to conservation of momentum from the enclosed liquid volume, circulation patterns develop through the entire tank volume. The circulation patterns are three-dimensional and quite complex. The circulation patterns persist after the fill cycle has ended, often for many hours. During the fill cycle, new liquid is dispersed through the entire volume via the circulation patterns provided: 1) the fill cycle is long enough and 2) temperature differences between inlet liquid and tank liquid do not produce circulation patterns that inhibit mixing

Selection

For liquid mixing in jet mixed tanks, there are two areas of work: determining the optimum jet angle and then determining the mixing time at that time. At angles that are far from optimum the mixing time will be much longer and there can be stagnant areas, particularly, if the jet intersects the far wall far below the liquid surface. This has always been an area of confusing in using the correlations. During sizing of Jet Mixer for particular duty many parameters have to consider to achieve desire mixing in specific time i.e. Tank Diameter, tank height, jet Velocity, jet Nozzle Diameter, jet angle, no of jets, properties of fluid.

Applications

- Jet mixing has ranged from the homogenization of hydrocarbon and LNG storage tanks to acid mixing and Dispersion of immiscible fluids.

- Jet mixer is used for blending the inhibitor into the monomer storage tank to stop violent run away of exothermic polymerization reactions Heat and Mass transfer and homogenization.

- Anaerobic Sludge digesters.

- Aerobic Sludge digesters.

- Aerobic and Anaerobic selector tanks.

- Solids Suspension.

Advantages

- No Moving parts hence low maintenance as compared to conventional Agitator

- It is cost effective for liquid and slurries.

- Easy to install when compared with impellers.

- Jet mixing leaves fewer dead spots in a shallow or rectangular tank than does Agitator.

- Long operating self life.

- Little wear and tear.

- Less energy consumption during solid suspension and gas contacting.

Design Standard

- ASME B31.3

- ASME B16.5

- ASME B16.47

- ASME SEC VIII DIV I

- ASME SEC VI DIV A/B/C

Material of Construction

- Carbon Steel

- Special Alloys

- Hastealloy

- Titanium

- Stainless Steel ( SS 304,SS 304L,SS 316,SS 316L)